- Construction technologies

- 8 likes

- 12488 views

of hollow ceramic blocks of buildings Construction technology Porotherm based on the same rules as the construction of buildings of brick, but using large-Porotherm blocks have certain features.

When laying Porotherm blocks not used masonry mixture vertical joints. Vertical blocks Porotherm groove connected to the system - the crest of which is provided a block structure. An exception is the angle forming the walls, which uses angle blocks and half

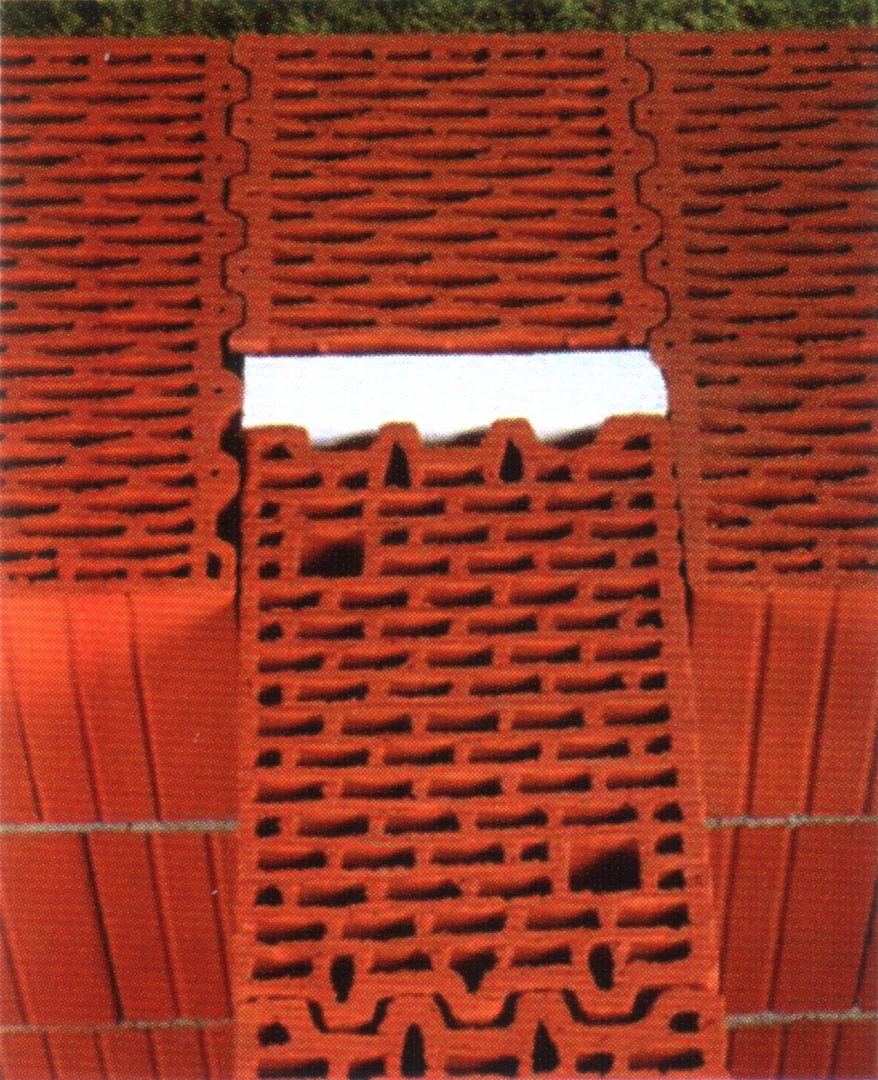

FIG. 1

Masonry mortar in the vertical joints need to use between integer and cutting blocks

For qualitative. performing laying of large format ceramic blocks necessary to align the zero level in the horizontal plane. For clipping capillary pull moisture into the bearing wall must perform waterproofing before the first row of blocks

. Large-blocks Porotherm to be installed so that the vertical joints in adjacent horizontal rows are shifted with respect to each other by half the block but not menie 10 cm in the walls of the whole block, and in the walls with Reza blocks shift allowed at least 4 cm

FIG. 2

When the length of the load-bearing wall is not a multiple of the size of Porotherm block, it is necessary to add on blocks to the desired size, and the vertical seam between the whole unit and cut a part to fill insulating masonry mortar . For cutting large-format ceramic blocks using a special saw electromechanical "alligator" or stationary disc saws with cutting depth greater than 25 cm

FIG. 3

add on units is recommended to invest in the wall as far as possible from the corners, window and door openings.

For construction of external walls of Porotherm blocks, a special heat insulating solution, e.g. LM-21 e production

Quick-Mix. Masonry blocks required when the outdoor air temperature is not lower than + 5C. Blocks must moisten with water, so that they do not absorb water from the solution vigorously. The thickness of the solution layer in the horizontal joints should be between 8-12 mm

. The clutch outer bearing walls of Porotherm blocks must begin with the formation of corners. For the formation side of the house should be used for final assembly of "angular" and "half-hearted" blocks that will ensure proper ligation of horizontal rows (Figure 1). At each corner of the clutch output on three rows, the blocks are then laid between the corners.

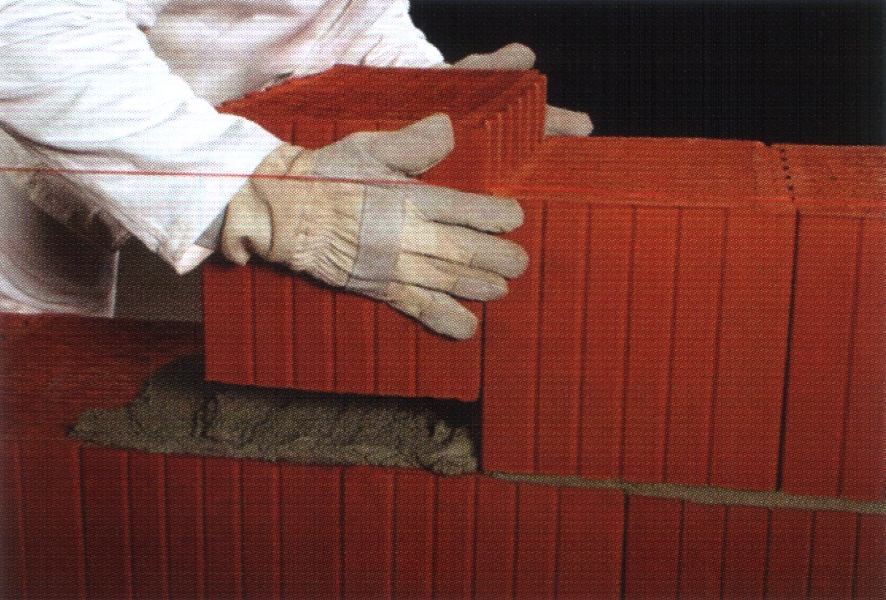

In order to avoid distortions in laying blocks Porotherm first joint in the vertical junction ridge-groove, and then lowered down on solution

FIG. 4

Control verticality of the walls at the corners is performed by using a plumb and level construction as in the small piece of masonry materials -from ceramic or siliceous brick. Control horizontality laying between the corners of the wall and the control plane is carried bricklayer using cord stretched between the corners

. The inner bearing walls of the ceramic Porotherm blocks must erect simultaneously with the erection of exterior walls . Odd block rows dock onto the outer wall, and the even rows are inserted into the outdoor unit, which is pre-trimmed 10-15 cm Compound outer wall and an inner insulated blocks 5 cm layer of insulation