- Construction technologies

- 8 likes

- 5897 views

The wall structure of brick, large format blocks must be designed in such a way that the entire period of operation of the building in any weather and climatic conditions of the wall bearing capacity corresponds to construction standards. . Maintain the integrity and bearing capacity of the wall can only be subject to the application of masonry equipment

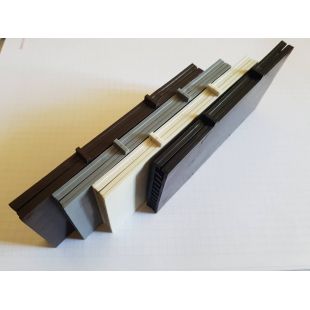

masonry equipment includes: anchor, horizontal bars, brackets, clamps, ventilation elements

The anchors are used for securing. flexible coupling main walls with face brick. According to the method of use of the anchor are: mortgages, which are laid directly into the masonry, while the construction of load-bearing wall and the facing, and the anchor for subsequent installation, when brick-lined building is carried out on the finished bearing wall.

facade is subjected to constant dynamic stresses that are generated pressure force and the vacuum force due to wind flows and temperature linear deformations, however, the coupling elements and between the facing main wall and exposed to compression and tensile stress. The material of which are made flexible connection must be durable, but at the same time and elastic to carry dynamic loads from the cladding to the core wall and in the opposite direction. Too strong, but flexible material does not allow to compensate for linear expansion of the outer walls when heated by solar heat, internal stress will occur, and this will lead to cracks in the facing brick. Therefore, the only material for the flexible links can only be stainless steel, which has more and anticorrosive properties. Nominal and practical way has been defined the optimal diameter of the anchor, which is 4 mm. The length of the flexible links is selected insulation thickness and air gap.

Anchor recommended to place 50 cm in horizontal rows and 40 cm vertically vrazbezhku. Additionally, you need to provide for binding of bricks around the door and window openings on the anchor 3 by 1 meter.

The temperature difference inside and outside the wall leads to a dew point between the facing wall and the carrier, which leads to the constant accumulation of moisture in the air gap and, hence, in the insulation. Insulation for ventilation and drainage of condensate outside wall is necessary to provide a device of natural ventilation. Employment of such a ventilation is provided via a special ventilating element-boxes. The ventilation box is mounted in the vertical seam at the bottom of the masonry walls, above and below the window openings, as well as in the upper part of the wall. In a multi-storey building ventilation boxes additionally arranged between each floor. It is recommended to place the box through clutches 50 cm.

Ventilation boxes provide ventilation layered luggage condensate withdrawn outward wall ventilation gap protect from rain and penetration into the wall of insects.