- Construction technologies

- 20 likes

- 8860 views

High gas prices, electricity forced to think: what materials to build a house to the winter heating costs, and in the summer on the air conditioning did not hit the family budget

Let's deal

Ukraine. acts building codes that define thermal performance of constructed structures: walls, windows, floors, roof, floor

. According to the DBN V.2.6-31: 2006 "Thermal іzolyatsіya budіvel» the value of thermal resistance for exterior walls should not be less than R = 3.3 m < sup> 2 C 0 / W

different materials have different thermal properties, which are characterized thermal conductivity λ . The smaller the ratio, the less the material conducts heat, and, therefore, it is better in store. Conversely, the larger the ratio, the worse the material retains heat

! There is one value that determines the thermal performance materiala- is resistance to heat transfer , is indicated by R . These characteristics are interrelated such formula: R = δ / λ, where δ - is the thickness of the material

To calculate how thick should the outer wall of the house, you need to use the formula R = δ / λ , remembering algebra we obtain: δ = Rλ , and according to our standards: δ = 3,3λ

Knowing the λ factor for a variety of materials, we can calculate the thickness of the enclosing structure different materials

. example :

wood (pine, fir) has λ = 0,18 W / m²K, forward wall thickness δ = 3,3h0,18 = 0.594 m. That is, fashion log cabins of logs to 30 centimeters really need to build on the thickness of the logs 2!

Consider another" warm "material - coquina

Block of rakushnyaka is λ = 0,40 W / m²K, expect wall thickness of rakushnyaka: δ = 3,3h0,40 = 1.32 m <! / span>

With dimensions rakushnyaka 40h20h20 see, actually a wall should be built in 3 blocks

<span! style = "font-size: 12pt;"> Ceramic hollow brick has λ = 0,47 W / m²K, forward wall thickness of the brick: δ = 3,3h0, 47 = 1.565 m

! The ceramic corpulent bricks (usual red brick ) has

λ = 0,56 W / m²K, forward wall thickness of the brick: δ = 3,3h0,56 = 1.848 ! m

in other words, to the house of red brick line with our thermo-technical standards, it is necessary to build a wall thickness of about 1.5 - 2 meters !

And all this on the theoretical performance of the thermal conductivity. But in reality, when these materials will gain operational humidity, everything will be even worse

! Naturally, such a sense of the fortress is not erect, so , has developed a variety of technologies to the outer wall was the usual for us the size of 40-50 cm, but at the same time, heating costs were minimal

most of all the construction technology of heat-wall based on the use of insulation materials. It: basalt wool, glass wool, foam glass, polystyrene and penouritanovye insulation, plaster on the basis of perlite and vermiculite

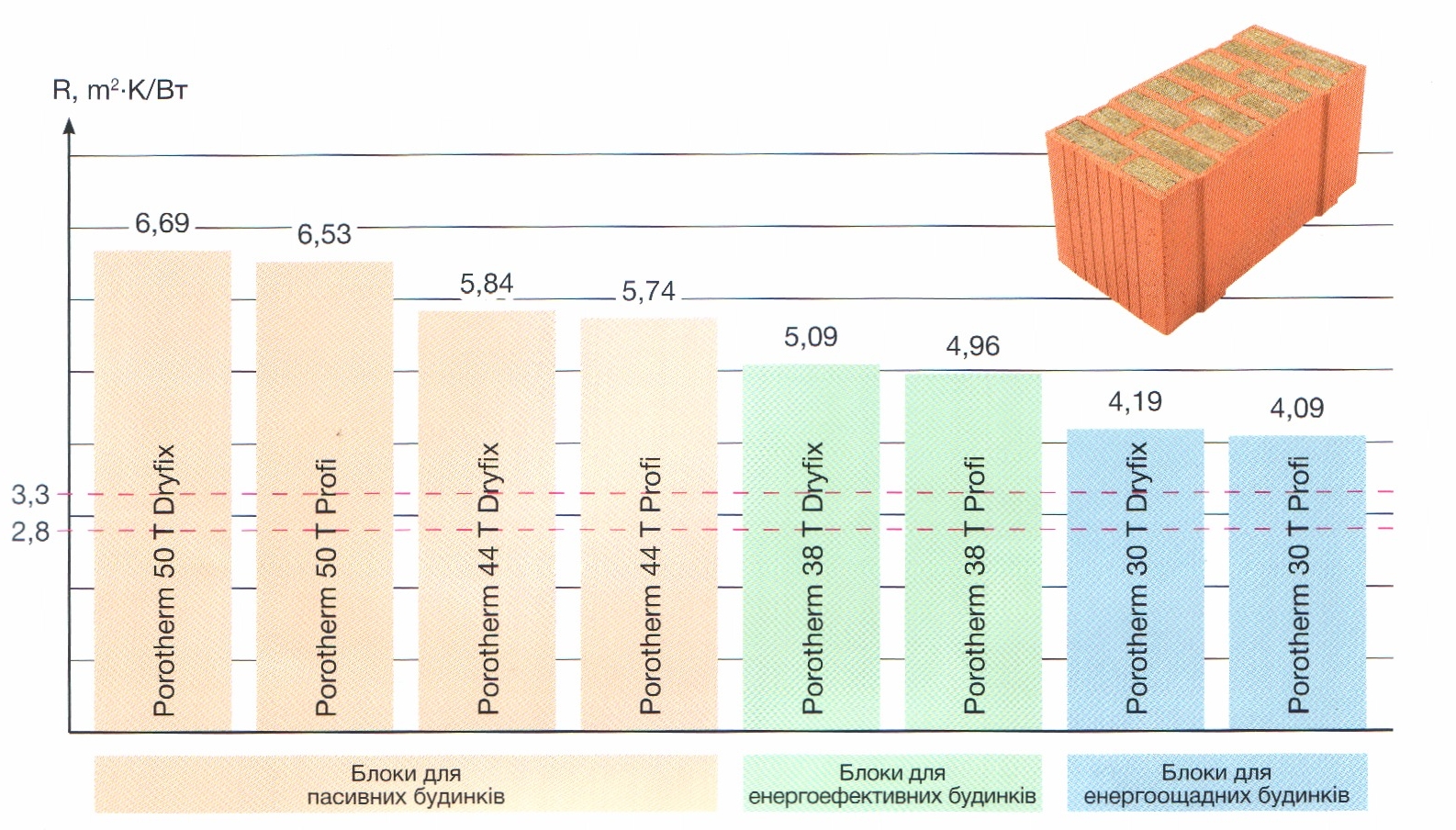

However, experts Austrian group Wienerberger have developed and established a series production of unique supporting blocks, made of porous ceramics, which allow to build a wall thickness of 44 cm without additional application of heat-insulating materials

The resistance value of the heat transfer wall of the ceramic hollow POROTHERM blocks 44 p + w is equal to 3.33 m 2 K / W, which corresponds to our standards

. If you want to save more on energy, that for you concern Wienerberger began releasing block POROTHERM 44 EKO + . These blocks heat transfer resistance is 4.35 mK / W, which is 30%above the regulatory

! Since 2015 Wienerberger concern began releasing the plant in Hungary new block Porotherm Klima , Blocks Porotherm Klima under standard external dimensions 30, 38 and 44 centimeters have a greater number of inner cavities series that explains their better heat-saving properties. When the thickness of the block 38cm have thermal resistance R = 3,66, which is 10%more than that required by DBN ( Details of these blocks in the publication The new heat-saving blocks Porotherm Klima )

.

For demanding customers who know how to count their expenses, group Wienerberger is an assortment of blocks with a thermal coefficient of resistance R = 5.88! This-saving ability possess blocks Porotherm 44 Termo , in which the internal voids filled with basalt wool ( read publication Blocks Porotherm Termo )

Technologists company Heluz developed and implemented in the production of ceramic blocks series Family 2 in 1 with the filling of internal voids with foam balls. These blocks have an even greater the thermal coefficient of resistance to R = 9.06

The range of ceramic blocks company MODERN HOUSE has an innovative system of Porotherm Dry Fix , developed by specialists of the Austrian group Wienerberger.

POROTHERM DRYFIX - this masonry system polished hollow ceramic blocks on foamed polyurethane adhesive for masonry

. The system uses a ceramic hollow blocks Porotherm DryFix , which are ideal geometric dimensions, due to additional grinding horizontal surfaces. To connect the hollow blocks in the system of special sprays are applied with polyurethane adhesive. Glue is applied to the horizontal surface of the blocks with a conventional gun foam, and requires no additional preparation. It's very simple and very innovative connection system of hollow ceramic blocks

.

System masonry POROTHERM DRYFIX allows to erect walls 2 times faster than traditional masonry walls POROTHERM blocks and 5 times faster construction of walls made of bricks! The ability to carry out masonry work in winter at negative temperatures down to -5 ° C. The possibility of loading the wall a few hours after their construction, since there is no grout, which is gaining strength in 28 days, and at low temperatures - much longer! It should be less unskilled workers due to lack cooking cycle masonry mixture. The ability to produce finishing work immediately after the erection of walls with lower cost materials, since the walls have an ideal geometry and contain moisture

. all this significantly reduces the commissioning dates of buildings, and therefore reduce the overhead costs associated with providing the construction cycle - the protection of the construction site, payment of temporary schemes of power, time-based compensation to employees and other expenses

<. p=""> and the most important economic benefit - it is an opportunity to start building operation faster and thus faster start profiting

main advantages walls HELUZ ceramic blocks, POROTHERM, Leier:

1. The wall of the ceramic blocks does not require reinforcement and fixings - savings on expensive metal

2.. Better load distribution - the wall of the ceramic block is homogeneous, thus less risk of cracking

3.. The wall of the hollow Porotherm blocks, Heluz lighter than brick wall with insulation:

4. Manufacturability - stacked blocks faster, do not need high qualification of workers

5.. Masonry mortar need 4 times less than for the walls of ordinary brick

6.. Ceramic blocks have good vapor permeability - walls "breathe", accumulate heat and smooth out sudden changes in ambient temperature, i.e. supported by a favorable microclimate for human space

7.. Ceramic blocks can withstand 100kg load per cm2, so one can build load-bearing walls without additional base plates

8.. Ceramic blocks have a very good performance on sound insulation to 55dB

9.. Ceramic blocks have low moisture absorption, and hence high resistance to frost

11.. Ceramic blocks - incombustible material 3 have refractoriness chasa

. 12. Ceramic blocks - it is 100%natural product

13.. Blocks Heluz, Porotherm are certified to ISO 9001

. The company "Modern house" presents the entire range of ceramic Heluz units:

Heluz Family, Heluz Plus, Heluz Family 2 in 1

and of Wienerberger:

Porotherm-8, Porotherm-11.5, Porotherm-25, Porotherm-30, Porotherm-38, Porptherm-44,

Porotherm-44 EKO +, Porotherm Klima, Porotherm Thermo

We Let's make < strong> Thermal calculation of the walls of different materials that would find the right size blocks and get the most energy savings.

By purchasing ceramic blocks, the customer can order the service . for the construction of the walls of these blocks

We will take on the care of all the shipping units to the construction site, unloading, storage and professionally executed construction works.